Printed circuit boards will be dissolvable in water

Ecology, recycling, sustainability. These terms form the mantra of most companies that want to keep up with the latest trends. Moreover, society (customers) also demands their consideration and the European Union supports them with a lot of subsidy programmes. It is, in short, a topical and timeless topic in many industries.

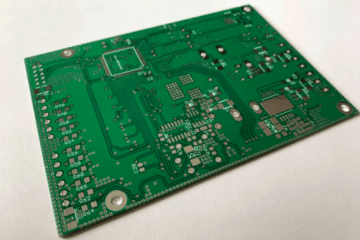

It seems that our industry has now also been hit by a major innovation in the field of sustainability. Printed circuit boards (PCBs), which have hitherto been a high environmental burden in terms of waste management, can now be recycled very easily. Just like, for example, the revolutionary PVA (polyvinyl alcohol) filament for creating support structures in 3D printing, which can be dissolved in water, PCBs will also be able to be dissolved in top water! This will also greatly simplify the recycling of other components on the PCB.

Revolutionary recycling

The biodegradable circuit board is made of natural fibres and halogen-free polymer. When it is placed in hot water, the board itself will disintegrate, making it easy to separate other materials and PCB components, greatly speeding up and simplifying the recycling process. Simply filter the water and remove the chips and electrical circuits.

This revolutionary technology has been pioneered by German company Infineon technologies AG using a plant-based PCB called Soluboard. As well as being recyclable by dissolving in water, the board also has a much smaller carbon footprint than conventional fibreglass PCBs.

Experts at Jiva Materials claim that replacing FR-4 PCB material with bio-based Soluboard in its production will reduce carbon dioxide emissions by 60%. In terms of numbers, that's 10.5 kg of carbon and 620 g of plastic per square metre of PCB.

Dissolving in minutes

The development of the unique plant material was handled by UK start-up Jiva Materials, and other companies are already working with it and looking at ways to use it in other types of electronics. For example, the University of Washington has already made a computer mouse out of Soluboard. In hot water, it can disintegrate in just six minutes.

We are closely monitoring further developments in biodegradable electronic components and will be actively involved in testing Soluboard in the near future so that we can include it in our product range as soon as possible. As you will already know, we have long supported ecology and sustainability and it is one of our top priorities for every project.