Case studies > E-Mobility - Portable WallBox EcoVolter

E-Mobility - Portable WallBox EcoVolter

Comprehensive development and optimization of the EcoVolter portable WallBox for R-EVC

R-EVC (Richtr-Electric Vehicle Connectors), a company specializing in the manufacturing and distribution of charging cables for electric vehicles across the European Union, faced a challenge regarding the transparency of its development process. Although they already had a developed and successfully marketed product – a portable WallBox – their original development model lacked transparency and was tied to the number of units sold. Over time, this model led to a loss of trust among their partners.

R-EVC therefore began searching for a new partner to establish a transparent, solid foundation for their development process from scratch. The goal was to set clear and sustainable collaboration principles that would foster long-term growth and trust among all stakeholders. That’s why they reached out to us at ASN Plus, where transparency in the development process is one of our core principles. As specialists in electronics, firmware, and communication application development, we are the ideal partner for those who require an efficient, clear, and transparent development cycle.

Since we received no data related to the existing device, the only option was to design the entire device from scratch, leveraging R-EVC’s experience as much as possible. As the first step, we conducted a thorough initial analysis, including defining all the requirements set by both the client and certification authorities. In the next step, we proposed significant improvements in the functionality of the device itself and the entire ecosystem.

Among these were features like the intelligent use of multiple communication technologies, allowing the portable WallBox to independently choose the most available connection. Everything can be easily controlled via a new mobile application.

We then moved on to the technical implementation of the project components, overcoming several challenges along the way. For instance, one of these was ensuring the existing hardware dimensions could be maintained even with substantial feature expansion, so that the injection-molding tools used for the stylish casing could still be used while meeting all relevant standards. The entire portable WallBox consists of several PCBs interconnected through the main control board. Our aim was to ensure seamless integration of all parts while maintaining a high level of functionality, modularity, quality, and compliance with the latest standards. Altium Designer was used for designing the circuitry and PCBs. In parallel with hardware development, we also worked on firmware development using development kits.

The main control unit is based on the advanced ESP32-S3 microcontroller, which integrates Bluetooth and Wi-Fi communication frontends. This microcontroller has dual cores and supports the RTOS operating system, which we fully utilized in developing our complex and sophisticated firmware. This architecture has enabled us to achieve a high level of reliability and security, essential for the stable and safe operation of the entire system.

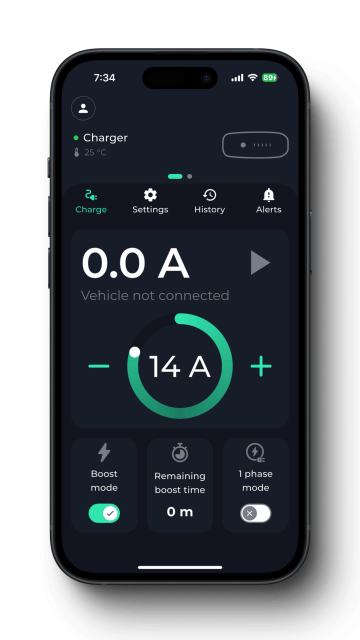

Initially, we implemented the device’s hardware functionality in accordance with the ČSN EN 61851 standard, ensuring protection for both the device and users, including automated safety tests, over-voltage protection, as well as overheating detection, undervoltage detection, and leakage current detection. We also implemented a smart charging function using a Control Pilot signal and phase switching, with support for single-phase and three-phase electric vehicle charging. Additional functions include network type detection, as well as charging voltage measurement and setting the appropriate charging current.

Transparent development process, smart charging and advanced mobile management of EV chargers

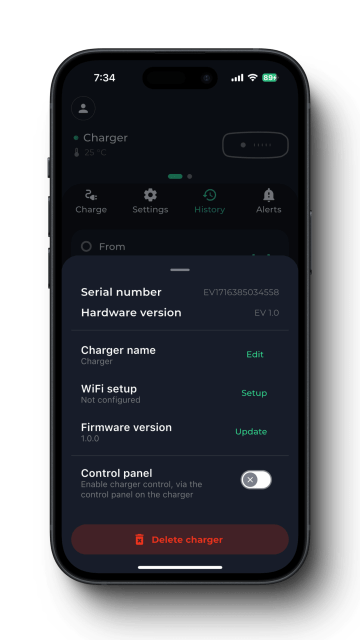

In the next development phase of the main control unit, we successfully implemented BLE communication, allowing full control and monitoring of the device directly from the mobile app. This feature provides users with easy access to managing the portable WallBox from their mobile devices, including setting charging parameters and schedules. The app also shows users how much they spent on individual charging cycles. We used the cross-platform Flutter framework for app development.

We also prioritized security by integrating software protection, ensuring that only authorized users or user groups have access to the device. This development phase also included implementing OTA (Over-The-Air) firmware updates, enabling simple wireless firmware updates directly via the mobile app, ensuring long-term support and updates without the need for physical intervention.

In developing the main control unit, we implemented Wi-Fi communication, allowing the device to automatically scan surrounding Wi-Fi networks and connect to known networks. If no known network is available, users can easily enter the appropriate password via the mobile app to connect the device to a new Wi-Fi. This approach provides end-users with convenient and flexible connection management. We then integrated several application-layer communication protocols, such as HTTPS, MQTT 5, and JWT (JSON Web Token), to ensure secure and reliable data transmission. Another key component of this phase was implementing the OCPP protocol, facilitating seamless integration and efficient management of portable WallBoxes, fully adapting the device to the needs of modern e-mobility infrastructure.

In addition to the main control unit, we also designed and developed several complementary hardware modules for R-EVC’s customers. These modules offer extended functionality and are designed to provide added value. All modules are built on the modern STM32C0 microcontroller, a cost-effective and available replacement for older 8-bit microcontrollers from ST. This choice optimized costs and improved availability for a wide range of applications.

One of the modules developed is a certified electric meter, which meets all MID (Measuring Instruments Directive) requirements and ensures highly accurate and reliable measurement of key physical quantities such as voltage, current, power, and energy consumption. This module is designed on the STM32C0 microcontroller platform in conjunction with the ATM90E36A chip and enables reliable communication with the main control unit via the Modbus RTU interface.

Another module we developed is an adapter board, which integrates directly into the portable WallBox connector. This module is designed for overheat detection of the connector, ensuring enhanced safety and protection during charging. Like the other modules, it is built on the STM32C0 microcontroller and communicates with the main control unit via the LIN protocol, allowing for efficient and reliable data exchange.

We also developed a “Tesla button” module for wireless opening of the EV charging port by pressing a button on the charger. This module is also designed on the STM32C0 microcontroller platform and includes an integrated RF chip with an antenna, providing reliable wireless communication for convenient control of the charging port.

Another module we developed is the LTE module, designed as an additional option for R-EVC customers. This module is used in cases where Wi-Fi connectivity is unavailable. It is configured as a plug-in module, equipped with a Quectel modem and a physical SIM card slot. Communication between this LTE module and the main control unit (ESP32-S3) takes place through the UART interface.

One of the implemented features is a local API running on an embedded HTTPS server directly within the WallBox unit. This interface provides secure endpoints for modifying charger configurations, monitoring its status, and managing user access. As a result, the device can be easily integrated into local control systems or corporate networks without requiring a cloud connection.

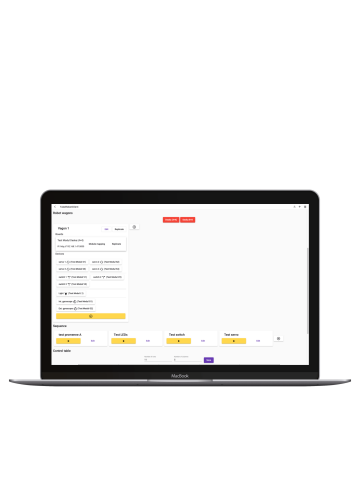

At the same time, we have developed a web application for managing users and charging stations, designed primarily for companies. This application enables centralized user management, displays charging history, and provides an overview of the energy consumption of individual vehicles. Based on this data, it is easy to perform energy consumption billing within corporate fleets.

For R-EVC, we also developed a separate desktop application for initial commissioning and quality control of chargers during production. Our collaboration with R-EVC continues with support for serial production and potential innovations based on the needs of their customers.

Summary:

-

ESP32-S3

-

ČSN EN 61851

-

Intelligent EV charging using Control Pilot signal

-

Current, voltage, temperature measurement

-

Phase count and network type detection

-

Over-voltage, undervoltage, overheating, leakage current detection

-

RTC, NVS, Modbus RTU

-

BLE communication with mobile app (Android, iOS)

-

OTA firmware update

-

Wi-Fi scanning and connectivity

-

HTTPS, MQTT 5, JWT

-

OCPP

-

STM32C0 ARM® Cortex®-M

-

MID certified electric meter

-

Adapter module with LIN communication

-

Tesla button

-

LTE module

-

Production desktop application

"Transparent, fast communication. Email or call - you get complete answers, fast. I don’t have time to build an in-house dev team; by the time I did, the opportunity would be gone. ASN Plus handled everything end-to-end, and much faster. In just one year, we built a brand-new device from scratch. Their cross-industry experience saves us serious money and keeps us moving forward."

Other referential projects

ZA200

Robotic optic cable laying

MP DRY CABINET

Chamber control unit

JeffTron

Electronics and apps for airsoft

Become one of our trusted clients

Take your product to the next level!

Book a consultation with our specialists and discover just how many technological possibilities are within your reach. We’ll be in touch soon to explore the best way to work together.